Climate Impact Partners is a trusted leader in the Voluntary Carbon Market (VCM), working with hundreds of the highest quality projects around the world. Whatever your requirements, we have a solution to meet your company’s climate goals.

Quality assurance is at the heart of what we do. Our clients rely on us to deliver climate solutions with real, sustainable and measurable impact. We work closely with our project partners to develop and deliver solutions that make real change possible.

Nature-Based Solutions

Nature-based solutions projects protect and enhance biodiversity to ensure our planet thrives. They can avoid and reduce emissions through nature conservation and remove emissions through nature restoration.

Learn moreHealth and Livelihoods

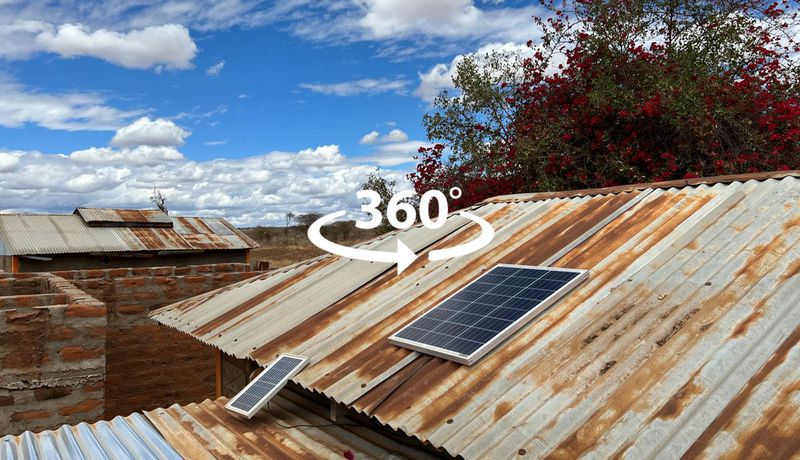

Health and livelihoods projects help households and communities decrease indoor air pollution, provide clean water, and raise household incomes, all while reducing global emissions. They are often located among communities that are most impacted by climate change, yet have the least responsibility for causing it.

Learn moreSustainable Infrastructure

Sustainable infrastructure projects accelerate the transition to renewable energy and decrease our dependence on fossil fuels. These large-scale technology solutions focus on the biggest sources of global emissions and reduce the carbon intensity of energy, transportation, and industry.

Learn more